● FEATURES 特性

1. High Q value and high self-resonant frequency with Ferrite material.

高Q值高SRF的铁氧体材料.

2. Small chip suitable for surface mounting.

小尺寸,表面贴装.

3. Tight inductance tolerance and high reliability.

高精度,高可靠性.

● APPLICATIONS 用途

1. Mobile phone TD-LTE/5G communication. 移动电话,TD-LTE , 5G通讯.

2. High frequency circuit in communication equipments. 高频线路的通讯设备.

3. Bluetooth , W-LAN , Broadband network. 蓝牙,无线宽带网络.

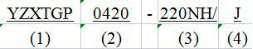

● PART NUMBERING SYSTEM 品名系统

(1) Type 型号 (2) External Dimensions 外形尺寸 (3)Indutance 电感值

(4) Indutance Tolerance 电感值公差(J:±5% K:±10% M:±20%)

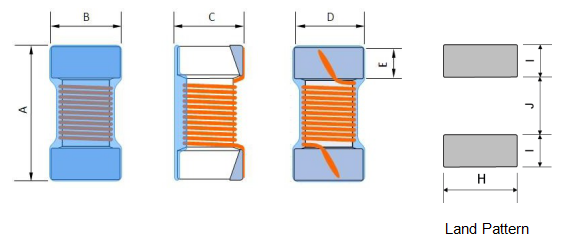

● SHAPES AND DIMENSIONS 外形尺寸 (Unit:mm)

TYPE(型号) | A | B | C | D | E | H | I | J |

YZXTGP0402 | 1.1±0.1 | 0.6±0.1 | 0.55±0.1 | 0.5±0.1 | 0.2±0.1 | 0.65 ref | 0.35 ref | 0.50 ref |

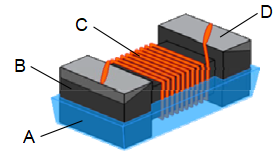

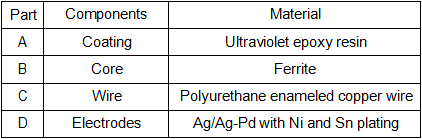

● STRUCTURE AND MATERIAL

● ELECTRICAL CHARACTERISTICS

1. Operating and storage temperature range (individual chip without packing): -25℃ to +125℃

2. Storage temperature range (packaging conditions): -10℃~+40℃ and RH 70% (Max.)

● TEST AND MEASUREMENT PROCEDURES

1. Inductance (L)

Test equipment: Keysight E4991B / Agilent 16197A or equivalent Test signal: -13dBm or 10mA

2. DC Resistance (DCR)

Test equipment: Agilent34420A / Agilent 4338B or equivalent

3. Q Factor (Q)

Test equipment: Keysight E4991B / Agilent 16197A or equivalent

4. Self-Resonant Frequency (SRF)

Test equipment: Keysight E4991B / Agilent 16197A / HP 8753E or equivalent Test signal: -20dBm or 50 mV

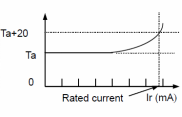

5. Rated Current (Irms)

Irms is direct electric current as chip surface temperature rose just 20 against chip initial surface temperature (Ta)

● RECOMMENDED SOLDERING TECHNOLOGIES

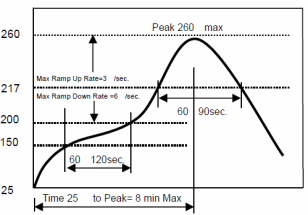

Re-flowing Profile

Preheat condition: 150~200 /60~120sec. Allowed time above 217C: 60~90sec.

Max temp: 260

Max time at max temp: 10sec Solder paste: Sn/3.0Ag/0.5Cu Allowed Reflow time: 2 times max

● SPECIFICATION TABLE:

YZXTGP0402 Series

Part Number | Inductance | Tolerance | Quality Factor | L/Q Test Freq. | Max. DC Resistance | Max. Rated Current | Self-resonant Frequency |

Symbol | L | Q (Typ) | Freq. | DCR | Irms | SRF (Min) | |

Units | MHz | Ω | mA | MHz | |||

YZXTGP0402-20nH/□ | 20nH | J,K,M | 10 | 100 | 0.050 | 1600 | 2600 |

YZXTGP0402-22nH/□ | 22nH | J,K,M | 10 | 100 | 0.072 | 1300 | 2500 |

YZXTGP0402-33nH/□ | 33nH | J,K,M | 10 | 100 | 0.060 | 1400 | 2300 |

YZXTGP0402-36nH/□ | 36nH | J,K,M | 10 | 100 | 0.092 | 1000 | 2300 |

YZXTGP0402-39nH/□ | 39nH | J,K,M | 10 | 100 | 0.150 | 830 | 2200 |

YZXTGP0402-51nH/□ | 51nH | J,K,M | 10 | 100 | 0.070 | 1100 | 1930 |

YZXTGP0402-56nH/□ | 56nH | J,K,M | 10 | 100 | 0.125 | 900 | 1900 |

YZXTGP0402-72nH/□ | 72nH | J,K,M | 10 | 100 | 0.100 | 900 | 1650 |

YZXTGP0402-78nH/□ | 78nH | J,K,M | 10 | 100 | 0.190 | 850 | 1600 |

YZXTGP0402-100nH/□ | 100nH | J,K,M | 9 | 100 | 0.160 | 900 | 1400 |

YZXTGP0402-140nH/□ | 140nH | J,K,M | 11 | 50 | 0.260 | 540 | 1220 |

YZXTGP0402-180nH/□ | 180nH | J,K,M | 11 | 50 | 0.330 | 560 | 1150 |

YZXTGP0402-200nH/□ | 200nH | J,K,M | 11 | 50 | 0.440 | 400 | 1000 |

YZXTGP0402-220nH/□ | 220nH | J,K,M | 11 | 50 | 0.530 | 380 | 1150 |

YZXTGP0402-250nH/□ | 250nH | J,K,M | 11 | 25 | 0.450 | 520 | 900 |

YZXTGP0402-270nH/□ | 270nH | J,K,M | 11 | 25 | 0.550 | 360 | 860 |

YZXTGP0402-300nH/□ | 300nH | J,K,M | 11 | 25 | 0.410 | 420 | 860 |

YZXTGP0402-330nH/□ | 330nH | J,K,M | 11 | 7.9 | 0.680 | 350 | 820 |

YZXTGP0402-360nH/□ | 360nH | J,K,M | 11 | 7.9 | 0.575 | 360 | 810 |

YZXTGP0402-390nH/□ | 390nH | J,K,M | 11 | 7.9 | 0.890 | 300 | 760 |

YZXTGP0402-420nH/□ | 420nH | J,K,M | 11 | 7.9 | 1.100 | 340 | 700 |

YZXTGP0402-470nH/□ | 470nH | J,K,M | 11 | 7.9 | 0.730 | 310 | 650 |

YZXTGP0402-560nH/□ | 560nH | J,K,M | 11 | 7.9 | 1.100 | 200 | 600 |

※□: Please specify the inductance tolerance code (J=±5%, K=±10%, M=±20%).

QQ客服

QQ客服